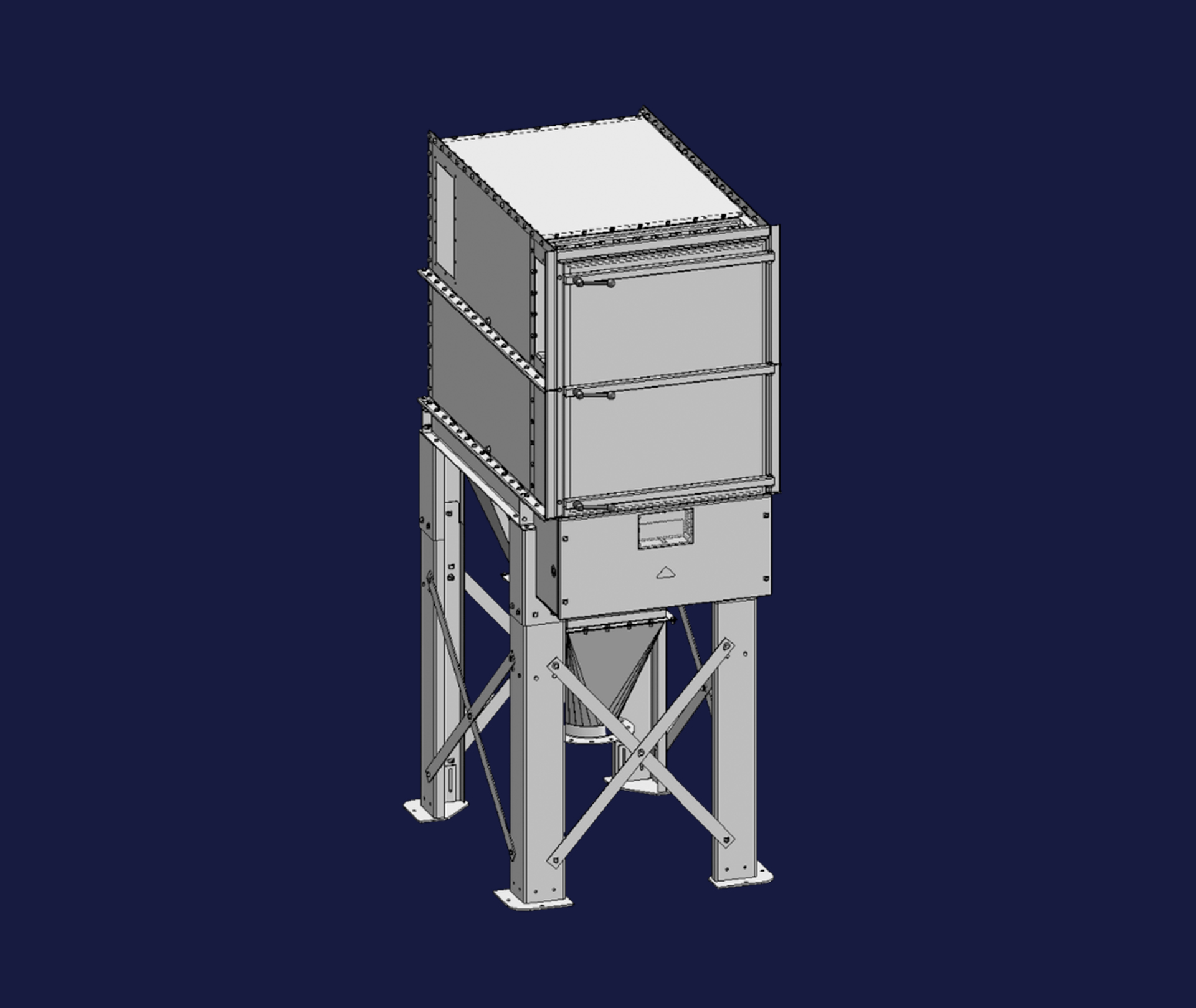

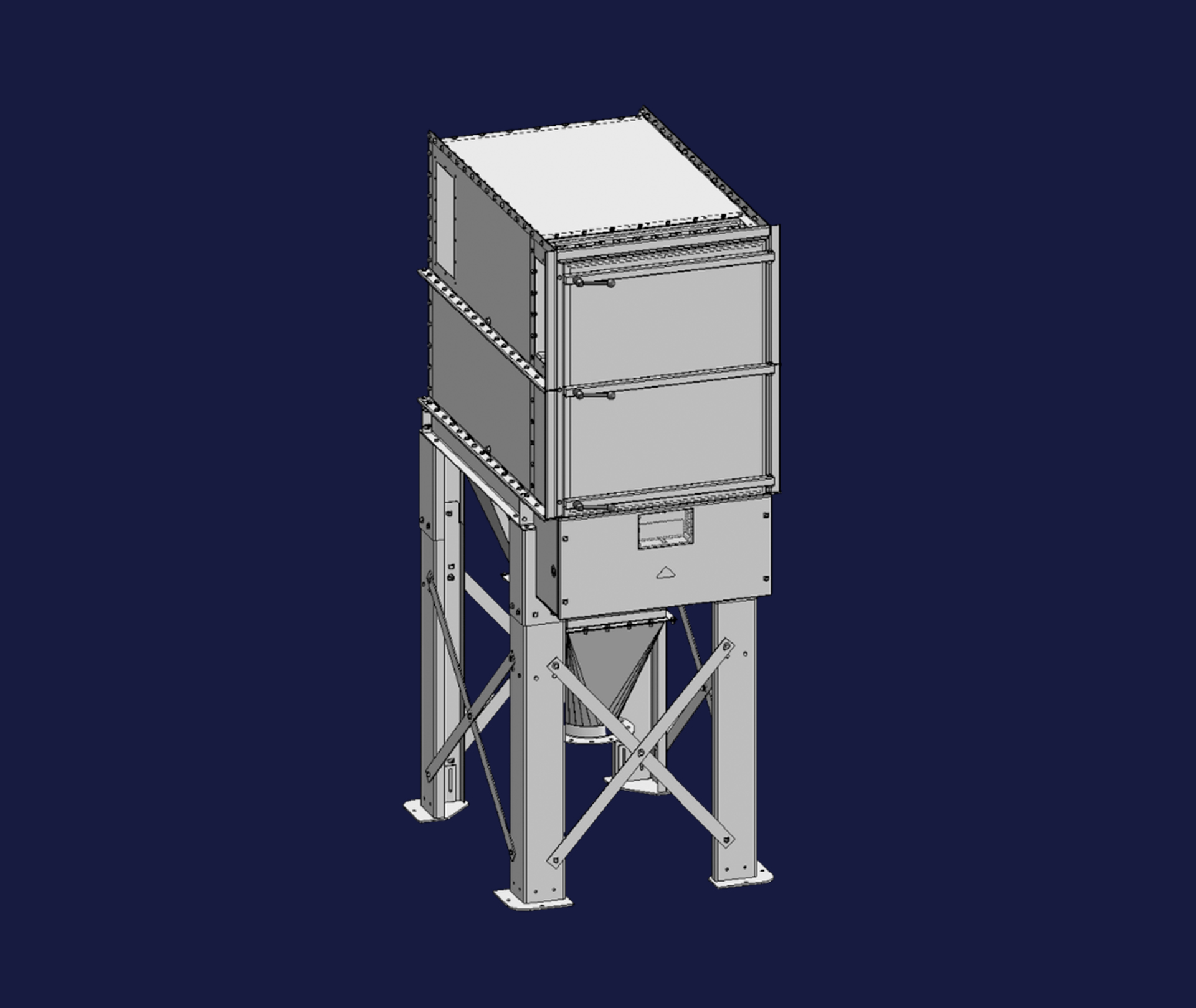

Case Filter

Separating dust or powder products from the air or processing gas.

Künzel case filters are used wherever dust or powder products are to be separated from the air or processing gas. We design our case filters to work safely and economically in an automatic production cycle.

They are fabricated from high-quality steel sheet and depending on the kind of use, all parts which come in contact with the product or gas can be produced from corrosion resistant steel.

| Type | Filter surface m² | Length mm | Depth mm | Height mm | Net weight kg |

|---|---|---|---|---|---|

| FG 10-1-1 | 10 | 1.685 | 1.004 | 1.131 | 410 |

| FG 10-1-2 | 12 | 1.685 | 1.004 | 1.731 | 570 |

| FG 10-1-3 | 30 | 1.685 | 1.004 | 2.331 | 720 |

| FG 10-1-4 | 40 | 1.685 | 1.004 | 2.931 | 1.100 |

| FG 10-2-4 | 80 | 1.685 | 2.006 | 2.931 | 1.450 |

| FG 15-1-1 | 15 | 2.185 | 1.004 | 1.131 | 725 |

| FG 15-1-2 | 30 | 2.185 | 1.004 | 1.731 | 900 |

| FG 15-1-3 | 45 | 2.185 | 1.004 | 1.131 | 1.150 |

| FG 15-1-4 | 60 | 2.185 | 1.004 | 2.331 | 1.350 |

| FG 15-2-3 | 90 | 2.185 | 2.006 | 2.931 | 1.450 |

| FG 15-2-4 | 120 | 2.185 | 2.006 | 2.931 | 1.850 |

| FG 15-3-3 | 135 | 2.185 | 3.008 | 2.331 | 2.200 |

Specifications are subject to change without notice.

The dusty air is drawn into the filter bags, where the dust settles on the outer surfaces, while the air passes through the material of the bags, (e.g. polyester needled felt) and escapes through the head piece insert on the clean air side of the filter. For continuous operation, all bags are cleaned regularly with compressed air.

An electronic pulse actuates the control valves, one after another in a repeated cycle. The control valve opens a diaphragm valve and a short impulse of compressed air is released, passing through the nozzles into the headpiece insert, back into the bag. By this reversed air flow direction, the filter bag is briefly inflated and the dust cake clinging to the outer surface of the bag falls into the dust collector.

Each filter is equipped with an electronically operating sequence regulator, controlling the cleaning cycle and the opening time of the valve. Cycle frequency and time duration can be adjusted to fit each application.

Numerous accessories are available, such as a sound insulation bonnet, differential pressure control, pressure proof castings, pressure release openings with bursting discs, anti static filter bag equipment, etc.