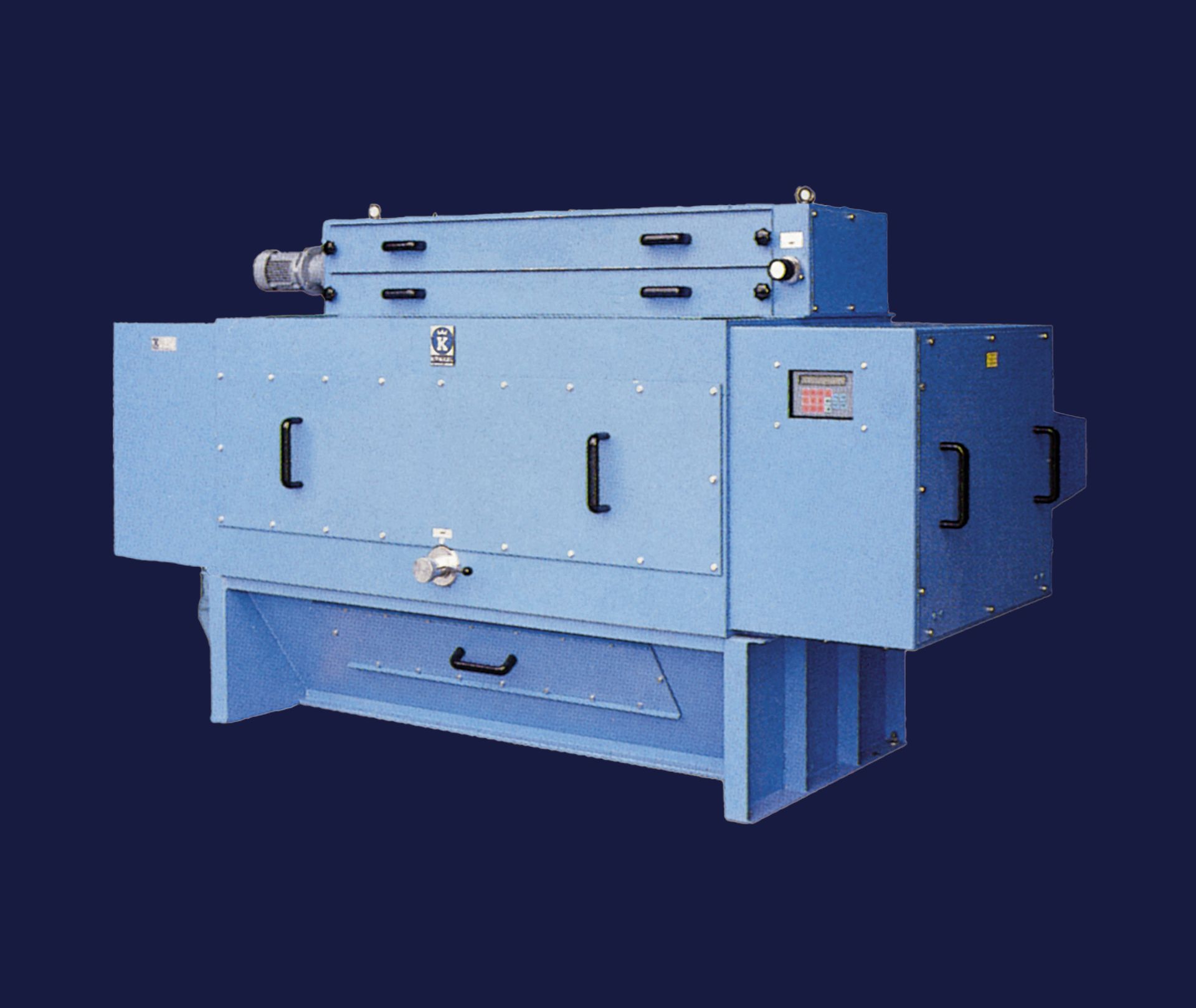

Adjunct Mills

Our mills excel due to their outstanding compliance and efficient design.

Our 2 and 4-roller mills are available for processing adjunct (rice, barley etc.), with capacities ranging from 250 to 10,000 kg.

In addition to grist mills and adjunct mills, Kunzel’s range of products includes all equipment items for the first process stage of the brewery, for malt intake up to the brewhouse: intake systems, silos, cleaning machines, scales, conditioning screws, conveying equipment, dust removal systems. These are available as individual components or as complete plants.

| Type | Milling capacity kg/h | Length mm | Width mm | Height mm |

|---|---|---|---|---|

| AS 25/80 | 2,000 – 2,900 | 1,886 | 1,520 | 1,035 |

| AS 25/100 | 2,500 – 3,800 | 2,136 | 1,520 | 1,035 |

| AS 25/125 | 3,000 – 5,000 | 2,386 | 1,520 | 1,035 |

| AS 25/150 | 3,500 – 6,000 | 2,636 | 1,520 | 1,035 |

| 20/30-2 | 800 – 1,000 | 860 | 840 | 590 |

| 20/60-2 | 1,600 – 2,000 | 860 | 1,140 | 590 |

| Type | Milling capacity kg/h | Length mm | Width mm | Height mm |

|---|---|---|---|---|

| 20/30-4 | 1,500 – 1,800 | 860 | 840 | 1,100 |

| 20/60-4 | 3,000 – 3,600 | 860 | 1,140 | 1,100 |

| AS 25/80-4 | 3,800 – 5,600 | 1,886 | 1,520 | 1,870 |

| AS 25/100-4 | 5,000 – 7,000 | 2,136 | 1,520 | 1,870 |

| AS 12/125-4 | 6,000 – 8,000 | 2,386 | 1,520 | 1,870 |

| AS 25/150-4 | 6,700 – 10,000 | 2,636 | 1,520 | 1,870 |