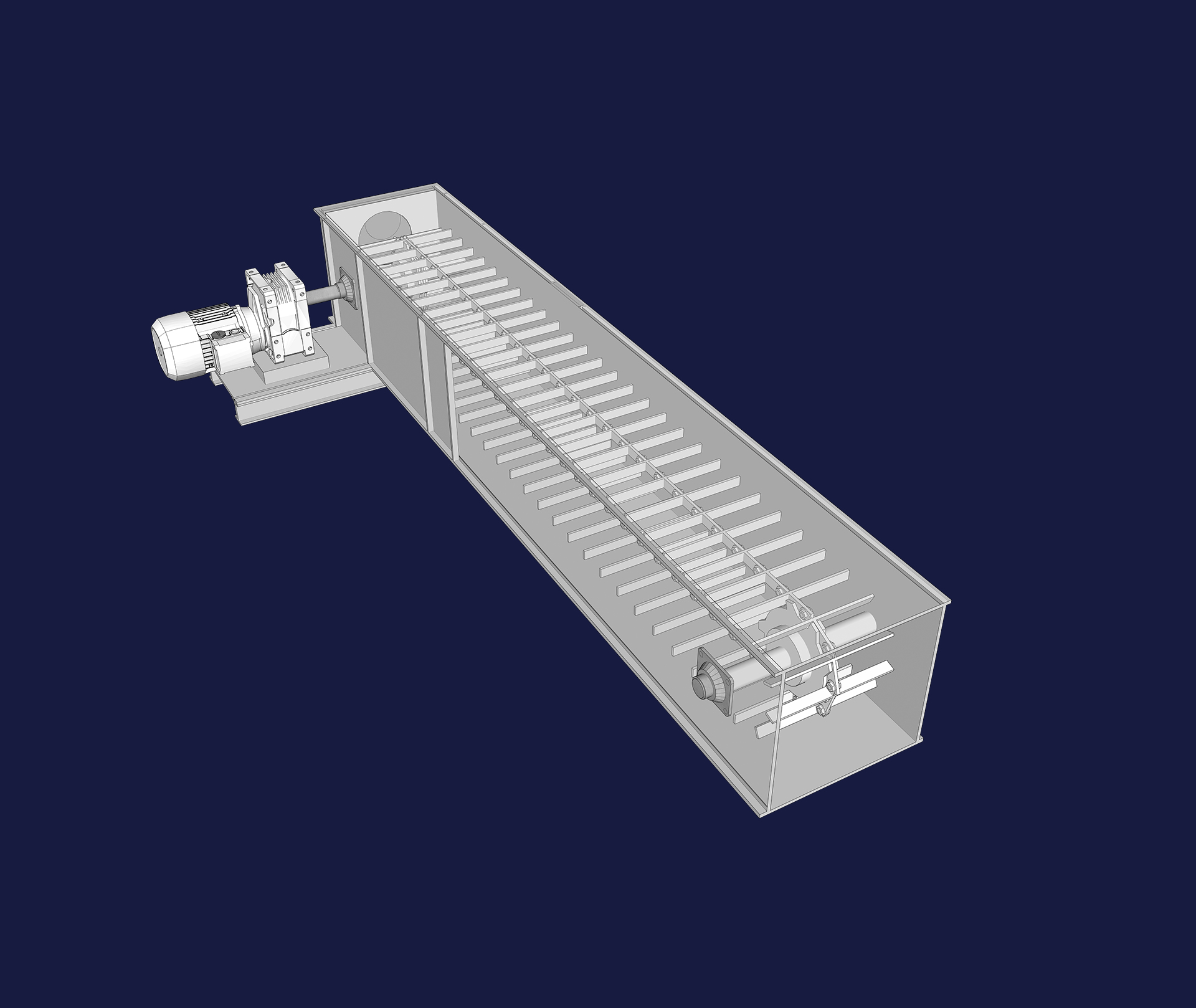

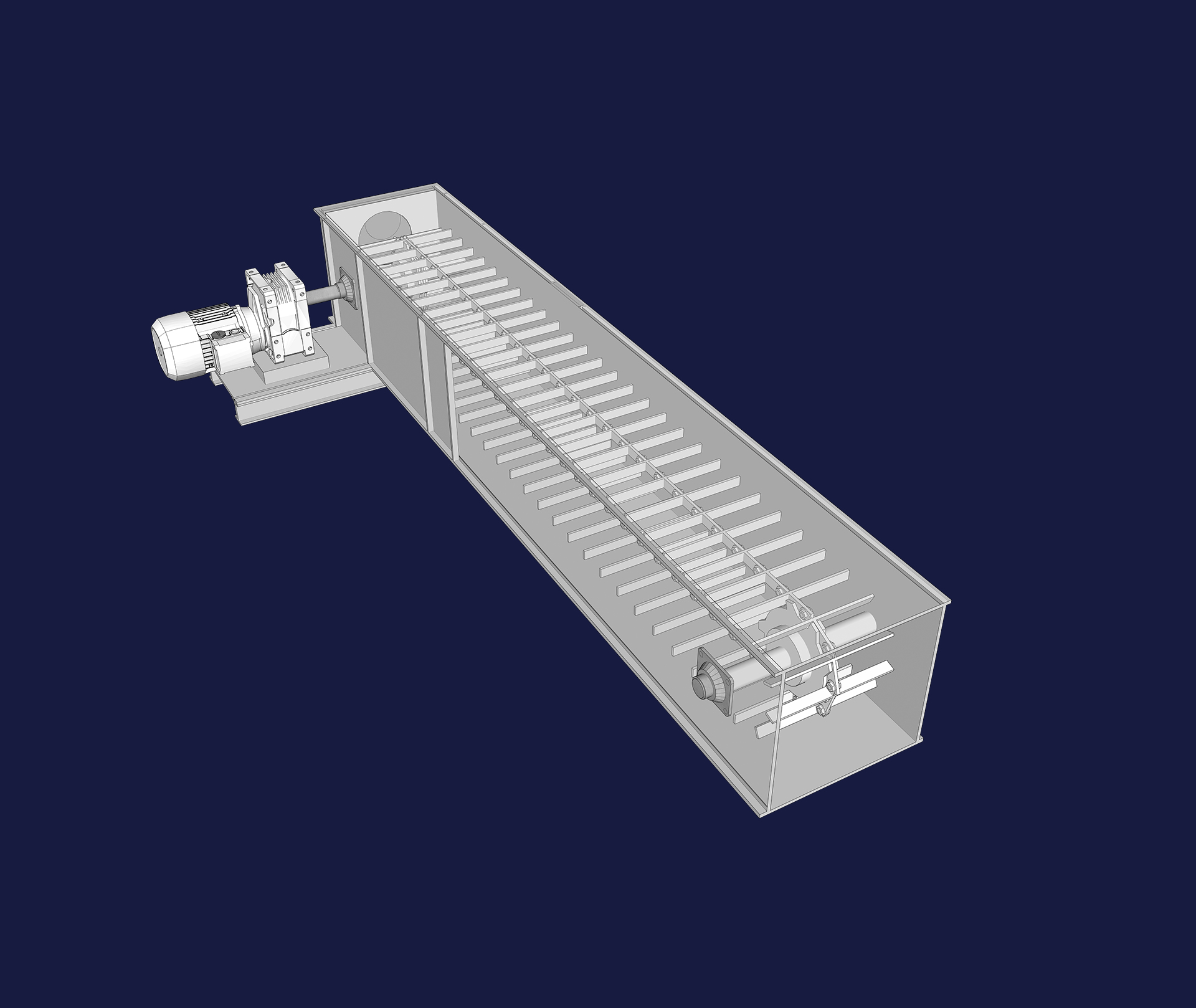

Trough Conveyors

Tailor-made to suit individual brewing needs and conditions.

The conveyors are available in several standard dimensions for a wide capacity range or can be individually designed and manufactured as special versions for many different applications and conveying capacities.

They can be equipped with several outlets depending on the application. Outlet slides are operated manually, pneumatically or electrically. If the chain conveyor is used with multiple inlets, a double bottom ensures smooth operation

Our chain / trough conveyors are robust and of high serviceability. There is a choice between the normal steel version with painted or galvanised surface and a stainless steel version. The cleaning equipment extensively avoids any mixing of materials caused by residues during the product change.

| Type | Chain speed m/s | Capacity m³/h | Malt conveying capacity t/h | Motor output kW | Length m |

|---|---|---|---|---|---|

| TKF 12/26 | 0,4 – 0,6 | 20 – 26 | 10,5 – 14,0 | 0,37 – 2,2 | 2,0 – 40 |

| TKF 15/40 | 0,4 – 0,6 | 37 – 48 | 20,0 – 25,9 | 0,55 – 4,0 | 2,0 – 40 |

| TKF 22/40 | 0,4 – 0,6 | 55 – 71 | 30,0 – 38,3 | 0,55 – 5,5 | 2,0 – 40 |

| TKF 30/40 | 0,4 – 0,6 | 74 – 97 | 40,0 – 52,3 | 0,75 – 9,2 | 2,0 – 40 |

Specifications are subject to change without notice. Other sizes are available upon request.

Künzel chain conveyors are safe to operate and are fitted with the following monitoring and safety elements:

All Künzel components are able to meet the requirements of explosion protection according to ATEX, NFPA or other country specific guidelines.