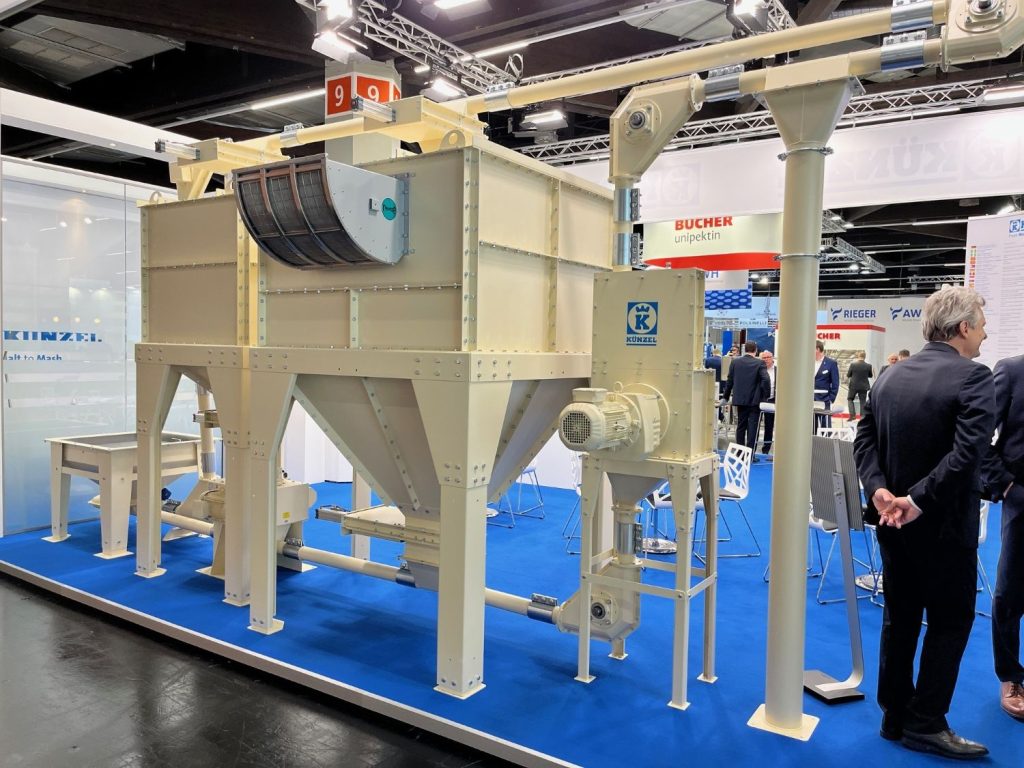

Compact Milling Plant

From malt to mash in a small footprint.

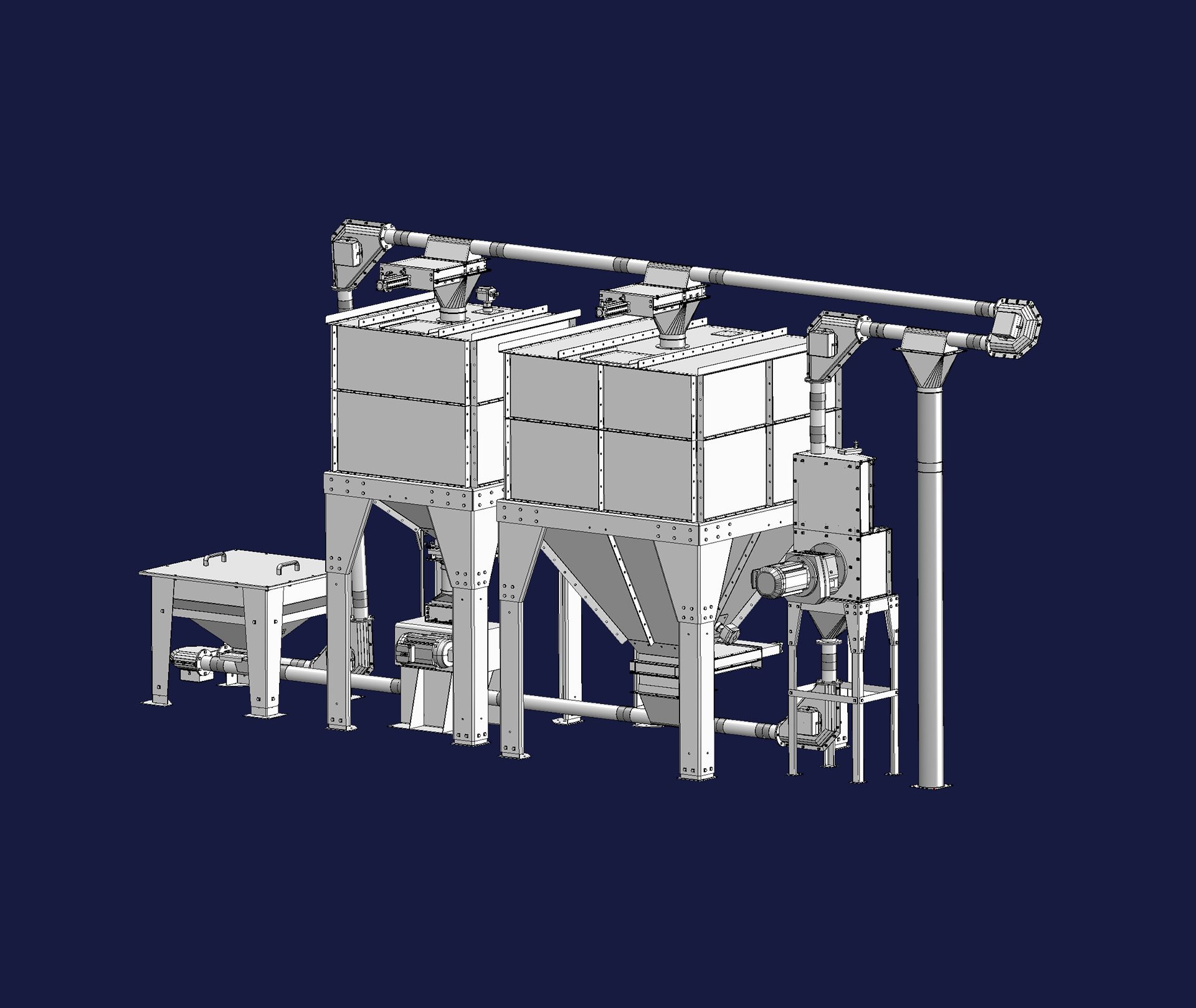

The Künzel Compact Milling Plant is a modular system that can be used to feed brewhouses in a batch range of 300 to 800 kg per brew.

The Künzel pipe chain conveyor forms the basis for our compact milling plant and is used to transport the received malt into the mill’s feed hopper and the fresh grist via the grist hopper into the mash tun.

Various sizes of bag feeding stations and big bag emptying stations are available for the malt feeding process. The quantity of material is determined either by counting the bags or by load cells under the feed hopper. Depending on requirements, our proven 2- and 4-roller mills can be combined with different bin sizes.

The Künzel KRK 90 pipe chain conveyor is a mechanical continuous conveyor for the gentle transportation of dry and free-flowing bulk materials.

Due to its modular design, it can be assembled into an individual three-dimensional conveyor and can be extended at any time. It can therefore be easily into almost any room (even where space is limited).

Various bag intake stations and big-bag stations are available for the addition of malt.

The bag intake stations can be selected in three different sizes. Attachments for ergonomic filling or aspiration hoods with point filters for dust-free working can be added. The Künzel big bag unloading station can be loaded either with a forklift truck or with its own lifting crane.

| Size selection (kg): | 50 | 100 | 150 |

|---|

With the modular storage and grist bins in six different sizes, the Künzel compact milling plant can be individually adapted to different brewhouse sizes.

The storage bin can optionally be equipped with load cells for precise recording of the bulk material. Our grist bins are pressure shock resistant and are equipped with explosion pressure relief devices to ensure a high level of safety.

| Size selection (kg): | 300 | 400 | 500 | 600 | 700 | 800 |

|---|

Our mills are characterised by a particularly robust design. They offer high operational reliability, minimal maintenance costs and a long service life.

Our mills of the type 16 series are available as 2-roller mills and 4-roller mills. All mills are equipped with a magnet box at the product inlet. The milling gap is individually adjustable for each pair of rollers.

| Type: | 16/16 | 16/30 | 16/16-2+2 | 16/30-2+2 |

|---|---|---|---|---|

| Number of rollers: | 2 | 2 | 4 | 4 |

| Capacity (kg/h): | 250 | 500 | 400 | 800 |

The level of automation can be freely selected, whether with manually or pneumatically operated slides, either stand-alone or integrated into the existing brewhouse control system – all designs are possible.